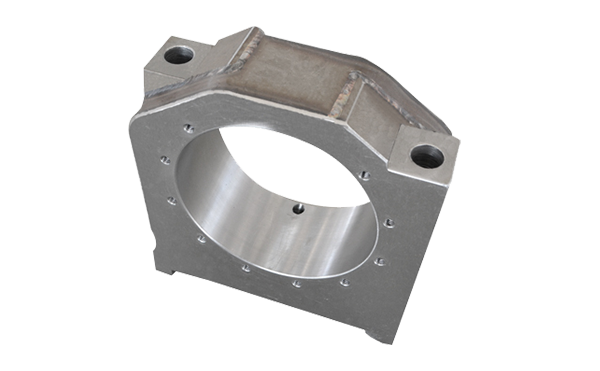

Rolling mill chocks

Release time:

2025-06-09

Rolling mill chocks are key components in rolling mills and play a vital role in the production process of metal rolling such as steel.

1. Structure and Design

Sturdy Construction

Rolling mill chocks are usually made of high-strength metal materials, such as high-quality cast steel or forged steel. This material selection ensures that they can withstand huge rolling forces.

Its structure is precisely designed with precise internal cavities to accommodate rolling mill bearings. The external shape is optimized according to the type and layout of the rolling mill to ensure stable installation in the rolling mill frame.

Adaptability

It has good adaptability with different types of rolling mill bearings, such as cylindrical roller bearings, tapered roller bearings, etc. The design takes into account the convenience of installation and disassembly of the bearings, and at the same time, it can effectively fix the bearings during operation to prevent them from displacement during rolling.

2. Functional Characteristics

Force Transmission and Support

During the rolling process, the rolling force is transmitted to the bearings through the rollers, and then transmitted to the frame structure of the rolling mill by the bearing seats. It can evenly disperse these huge forces, avoid local stress concentration, and thus protect other parts of the rolling mill.

Providing precise support for the rolls and ensuring the concentricity and verticality of the rolls during the rolling process is essential for rolling high-precision metal plates, profiles and other products.

Stability guarantee

Since the rolling mill will vibrate when running at high speed, the rolling mill chocks effectively reduce the vibration amplitude of the rolling mill with its own weight and stable structure. This not only improves the surface quality of the rolled products, but also extends the service life of the rolling mill.

Its good heat dissipation performance also helps to ensure that the bearings work within a suitable temperature range during the long rolling process, avoiding bearing damage due to overheating, and further ensuring the stable operation of the rolling mill.

3. Maintenance and care

Easy to check

Its design facilitates maintenance personnel to check the working status of the internal bearings. Through the reserved inspection port or easily removable parts, it can be timely discovered whether the bearings have problems such as wear and insufficient lubrication.

Durability

Rolling mill chocks made of high-quality materials and advanced manufacturing processes have a long service life. However, during use, regular cleaning, lubrication and inspection of key parts are still required to ensure its performance is always in optimal condition.

Key words:

Rolling mill chocks

Real-time information

Understanding the Manufacturing Process of Slab Caster Rolls: A Comprehensive Guide

Understanding the Manufacturing Process of Slab Caster Rolls Table of Contents 1. Introduction to Slab Caster Rolls 2. Raw Materials Used in Manufacturing Slab Caster Rolls 3. Detailed Manufacturing Process of Slab Caster Rolls 3.1. Casting Techniques 3.2. Heat Treatment Processes 3.3. Machining Techniques 3.4. Quality Control M

Understanding Casting Bearing Seats: Essential Components for Industrial Applications

Casting bearing seats play a vital role in the functionality and efficiency of industrial machinery. These components serve as the foundation for bearings, providing crucial support and alignment necessary for smooth operation. Understanding what casting bearing seats are, how they are designed, and their applications can greatly benefit professionals in the industrial sector. At their core, casti

Why Material Choice Matters in Caster Bearing Housings: A Comprehensive Guide

Why Material Choice Matters in Caster Bearing Housings Caster bearing housings are essential components in various industrial applications. They provide support and alignment for bearings, ensuring smooth movement and efficient operation of equipment. However, the effectiveness of these housings significantly depends on the materials used in their construction. Understanding the importance of mate

Address: No.1 Hengan Road, Tianning District, Changzhou City (Zheng Lu Heping Industrial Park)

Contact: Mr. Xu

Mobile:13815019479/15261117373

E-mail:xujiahui24@163.com/baihuixj@163.com

Copyright©2024 Changzhou Baihui Machinery Manufacturing Co., Ltd. Rights Reserved.