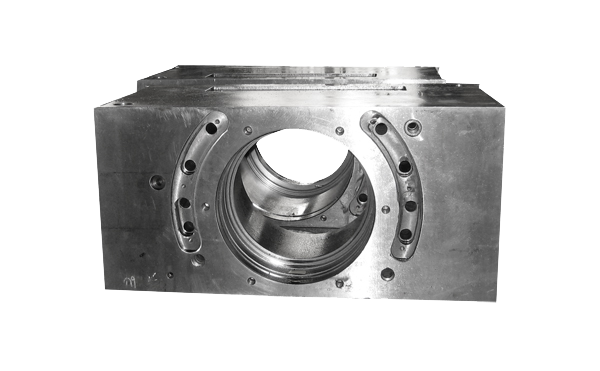

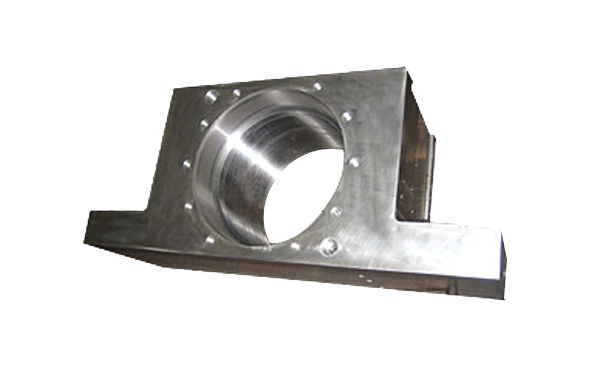

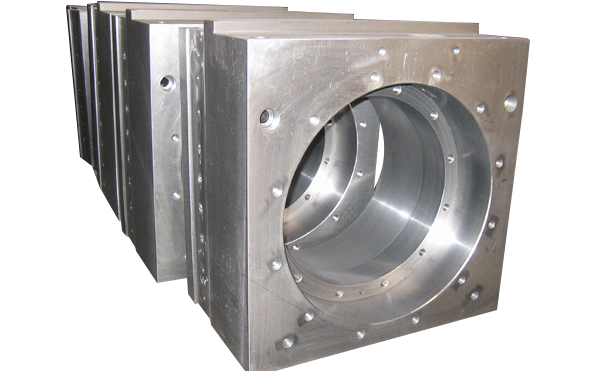

Rolling mill bearing housing

Classification:

Specializing in the production of metallurgical steel industry continuous casting machinery and equipment bearing, continuous casting rolls and other roll parts series and small rolling mill bearing series products

Key words:

Rolling mill bearing housing

Message

Message

Product Details

The roll neck bearing is a core supporting component in rolling mill equipment, directly affecting the stable operation of the rolls, rolling accuracy, and equipment life. Its main functions include supporting the rolls, bearing the rolling force, ensuring centering accuracy, and adapting to extreme working conditions such as high speed, heavy load, and high temperature.

In addition, the design and manufacturing of roll neck bearings require high precision. They usually use high-strength, high-wear-resistant, and high-temperature-resistant alloy materials to ensure their stability and reliability under long-term huge rolling pressure and complex stress environments. To effectively dissipate heat and reduce operating temperature, modern roll neck bearings often have built-in efficient cooling systems that use circulating coolant to prevent material degradation and bearing damage caused by overheating. At the same time, advanced lubrication technology is also widely used in bearing housings to reduce friction, extend service life, and further improve rolling efficiency and product quality. With the advancement of technology, the introduction of intelligent monitoring and maintenance systems enables real-time monitoring and early warning of the operating status of the roll neck bearings, allowing for the timely detection and handling of potential failures to ensure the continuous and stable operation of the rolling production line.

Recommend products

undefined

ONLINE MESSAGE

* We will contact you within one working day. Please pay attention to your email.

Address: No.1 Hengan Road, Tianning District, Changzhou City (Zheng Lu Heping Industrial Park)

Contact: Mr. Xu

Mobile:13815019479/15261117373

E-mail:xujiahui24@163.com/baihuixj@163.com

Copyright©2024 Changzhou Baihui Machinery Manufacturing Co., Ltd. Rights Reserved.