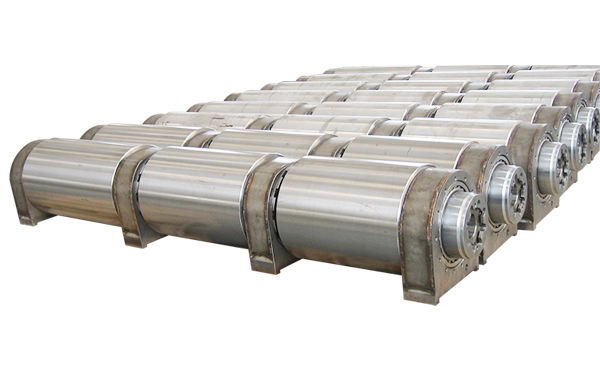

Continuous casting rolls

Classification:

Specializing in the production of metallurgical steel industry continuous casting machinery and equipment bearing, continuous casting rolls and other roll parts series and small rolling mill bearing series products

Key words:

Continuous casting rolls

Message

Message

Product Details

In the field of modern steel and non-ferrous metal casting, continuous casting rolls play a crucial role, and our continuous casting rolls have become an ideal choice for many casting enterprises due to their excellent performance and reliable quality.

High quality materials create sturdy quality

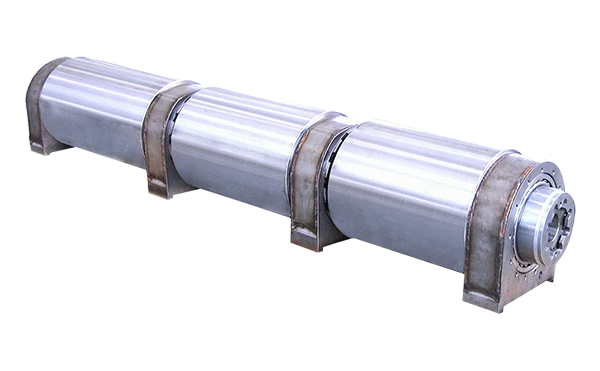

Our continuous casting rolls are made of special alloy materials that have been carefully selected and rigorously tested to possess high strength, hardness, and excellent wear resistance. In harsh continuous casting environments with high temperature, high pressure, and strong corrosion, continuous casting rolls can still maintain stable performance, effectively resist wear and thermal fatigue, greatly extend their service life, reduce replacement frequency, and lower production costs for enterprises.

Advanced technology ensures precise performance

By utilizing advanced manufacturing techniques, the surface processing accuracy of continuous casting rolls is extremely high, ensuring the flatness and roundness of the roll surface. This precise performance enables steel billets or non-ferrous metal billets to pass evenly through the roller conveyor during continuous casting, ensuring the dimensional accuracy and surface quality of the product. Meanwhile, the special heat treatment process further enhances the comprehensive performance of Continuous Casting Rolls, enabling them to better adapt to different requirements of continuous casting processes.

Efficient cooling design improves production efficiency

Continuous casting rolls are equipped with an efficient cooling system that can quickly dissipate the heat generated during the continuous casting process, effectively controlling the temperature of the rolls. This not only improves the thermal stability of continuous casting rolls, but also accelerates the cooling rate of castings, thereby increasing the speed and efficiency of continuous casting production. A stable cooling effect can also reduce the occurrence of surface cracks on the cast billet and improve the yield of the product.

Customized services to meet diverse needs

We are well aware that different customers have differences in continuous casting processes and product specifications, so we provide customized services. Based on the specific needs of our customers, we can design and manufacture continuous casting rolls of different sizes, materials, and performance to ensure perfect compatibility with various continuous casting equipment and production processes.

Whether it is a large steel enterprise or a non-ferrous metal foundry, our continuous casting rolls can provide reliable support, helping enterprises achieve efficient and stable production. Choosing our Continuous Casting Rolls means choosing exceptional quality and sustained success.

Recommend products

undefined

ONLINE MESSAGE

* We will contact you within one working day. Please pay attention to your email.

Address: No.1 Hengan Road, Tianning District, Changzhou City (Zheng Lu Heping Industrial Park)

Contact: Mr. Xu

Mobile:13815019479/15261117373

E-mail:xujiahui24@163.com/baihuixj@163.com

Copyright©2024 Changzhou Baihui Machinery Manufacturing Co., Ltd. Rights Reserved.