About Us

Changzhou Baihui Machinery Manufacturing Co., Ltd. was established in 1998. It is a professional manufacturer of bearing seats for continuous casting machinery equipment in the metallurgical and steel industry, roller series components such as continuous casting rolls, and small rolling mill bearing seat series products. It is a long-term designated cooperative enterprise of China Heavy Machinery Co., Ltd., China Shougang Group, China Baosteel Group, MCC Jingcheng Engineering Technology Co., Ltd., Wuyang Iron and Steel Co., Ltd., Ma'anshan Iron and Steel Co., Ltd., Ansteel Group, Pohang Iron and Steel Group of South Korea, Changshu Danieli Metallurgical Equipment Co., Ltd., Shandong Iron and Steel Group Jigang Group Co., Ltd., Tongyu Heavy Industry Changzhou Haijie Metallurgical Machinery Manufacturing Co., Ltd., Hunan Hualing Xiangtan Iron and Steel Co., Ltd., as well as Guangdong Shaoguan, Dalian Huarui Heavy Industry Group Co., Ltd., Shanghai Ximak Demag and other metallurgical heavy machinery enterprises.

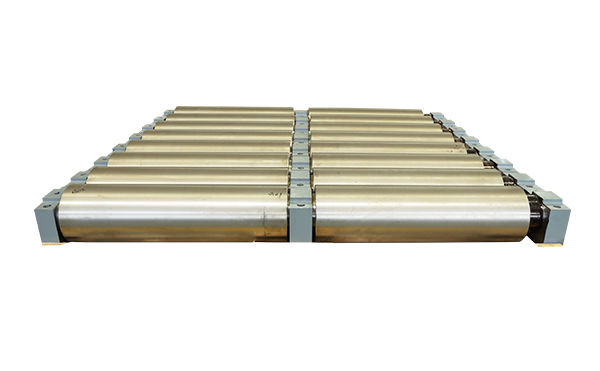

Explore Details →Monthly continuous casting complete roll set

Professional equipment

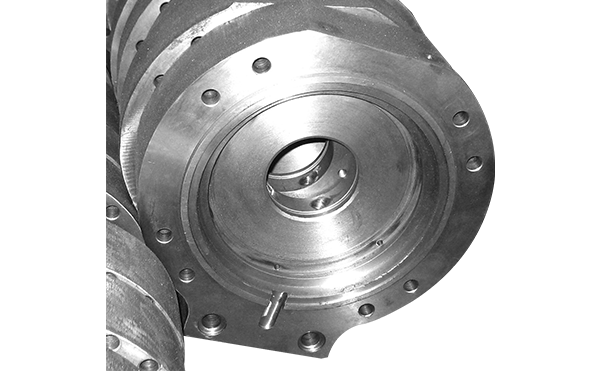

Monthly Continuous Casting Bearing Seat

Monthly continuous casting complete roll set

Product Center

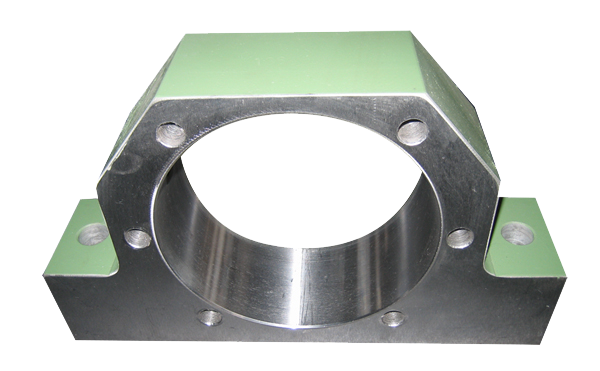

The mill bearing housing is a core supporting component in rolling mills, directly affecting the stable operation of the rolls, rolling accuracy, and equipment lifespan. Its main functions include supporting the rolls, bearing the rolling force, ensuring centering accuracy, and adapting to extreme working conditions such as high speed, heavy load, and high temperature.

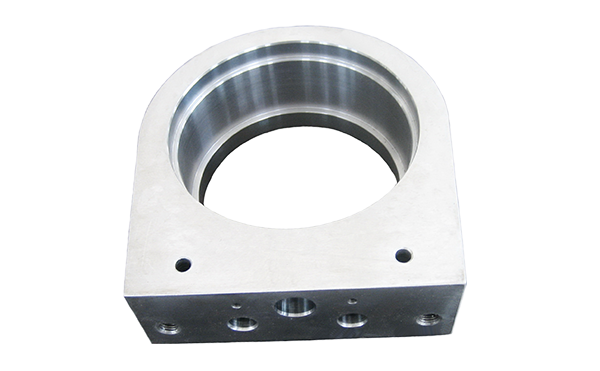

Roller conveyor bearing housing series

Roller bearing housings are key components in continuous casting machines and rolling mills that support rollers. They are used to fix bearings, bear loads, and ensure smooth roller operation, while also adapting to harsh working conditions such as high temperatures, high loads, and dust.

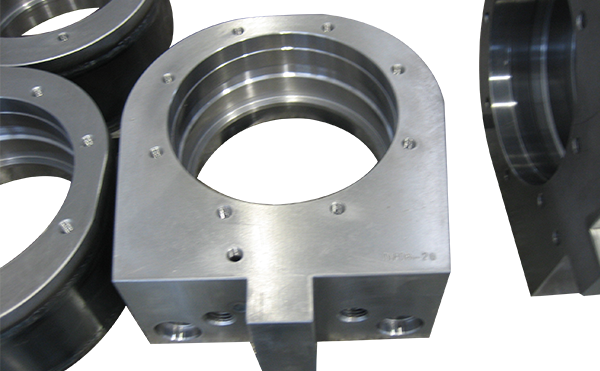

Continuous casting convex key bearing seat

The continuously cast convex key bearing seat is a special bearing seat design in the fan-shaped section of the continuous casting machine, mainly used for precise positioning and fixing of the continuous casting rollers, while adapting to the high temperature, heavy load, and frequent centering adjustment needs in the continuous casting process.

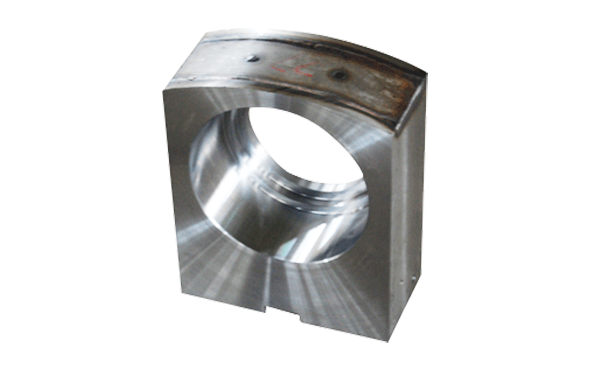

Twin-hole continuous casting bearing seat

Twin-hole bearing seats play a crucial role in continuous casting machines (continuous casting equipment), primarily used to support and secure the continuous casting rolls (or sector rolls), ensuring the stable operation of the casting billet during the solidification and conveying process.

Continuous casting porous bearing seat

The multi-hole bearing housing is a special bearing housing designed for the roll system of a continuous casting machine. Its core feature is the integrated cooling channels, which reduce bearing temperature through direct water cooling or air cooling to adapt to the high-temperature, heavy-load, and dusty harsh conditions of continuous casting machines.

Danieli series rotary joint bearing

Danieli Metallurgical Equipment Co., Ltd. is a century-old steel industry equipment manufacturer and one of the world's three leading metallurgical equipment manufacturers. Our company has long provided supporting services for its steel production, committed to producing world-class continuous casting bearing seats.

Danieli Metallurgical Equipment Co., Ltd. is a century-old steel industry equipment manufacturer and one of the world's three leading metallurgical equipment manufacturers. Our company has long provided supporting services for its steel production, committed to producing world-class continuous casting bearing seats.

The CIMAC Group is a metallurgical equipment design and manufacturing company with a history of more than 150 years. Our company has long provided supporting services for its steel production, producing world-class continuous casting bearing seats.

In steel production, the roll is the core component of the rolling mill, directly involved in the plastic deformation of metal, playing a decisive role in the shaping, dimensional accuracy, surface quality and production efficiency of steel.

In steel production, the roll is the core component of the rolling mill, directly participating in the plastic deformation of the metal, and playing a decisive role in the shaping, dimensional accuracy, surface quality, and production efficiency of the steel.

In the steel production process, the roll is the core component of the rolling mill, directly participating in the plastic deformation of the metal, and playing a decisive role in the forming, dimensional accuracy, surface quality, and production efficiency of the steel.

In steel production, the roll is the core component of the rolling mill, directly participating in the plastic deformation of the metal, and playing a decisive role in the shaping, dimensional accuracy, surface quality, and production efficiency of the steel.

In the rolling process of the steel industry, dry rolls (mandrels) are specially designed roll components mainly used in seamless steel pipe rolling (such as Assel rolling mills, Accu-Roll rolling mills, etc.) and the production of some special profiles. Its core function is to reduce the wall thickness, extend and shape the hollow tube blank through a lubrication-free, high-temperature direct contact method.

Dry roller (with water jacket)

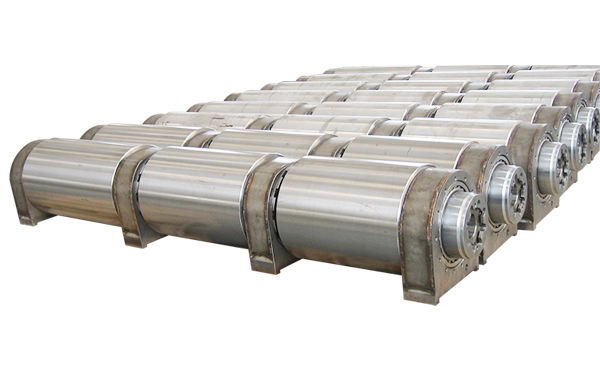

Dry roller (with water jacket) is a key auxiliary component specifically used for cooling and supporting rolling mills, mainly applied in hot rolling processes (such as hot continuous rolling of plates and strips, and section rolling). Its core function is to achieve efficient cooling, prevent overheating and deformation of rolling mills, and ensure the stability of the rolling process.

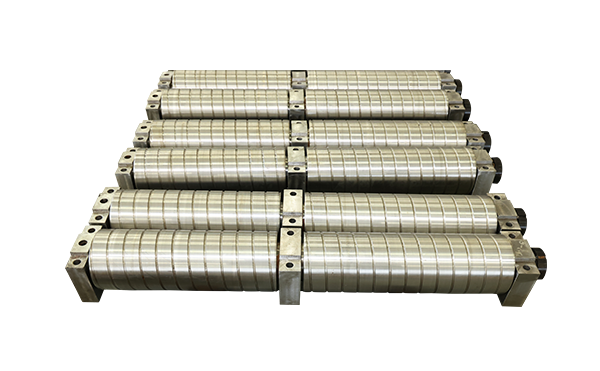

Roller conveyors are indispensable transportation and support equipment in the steelmaking process, widely used in rolling production lines, heat treatment lines, and finished product conveyor lines

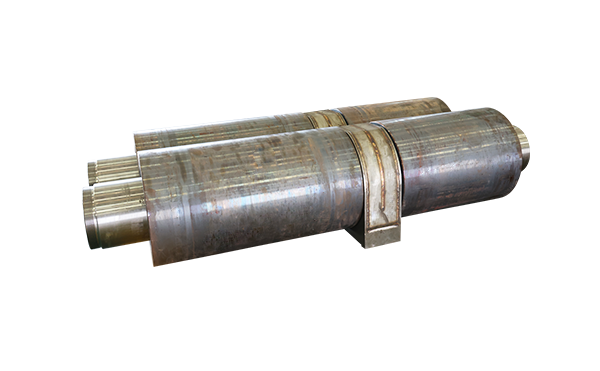

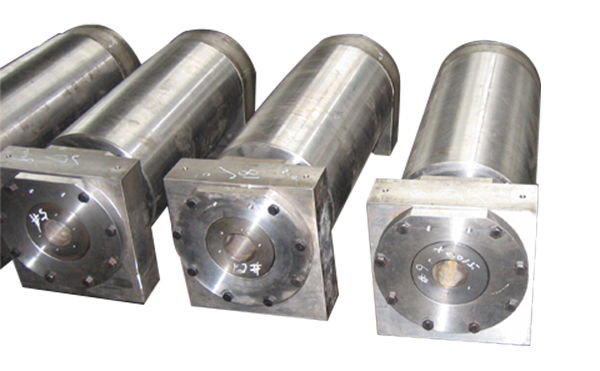

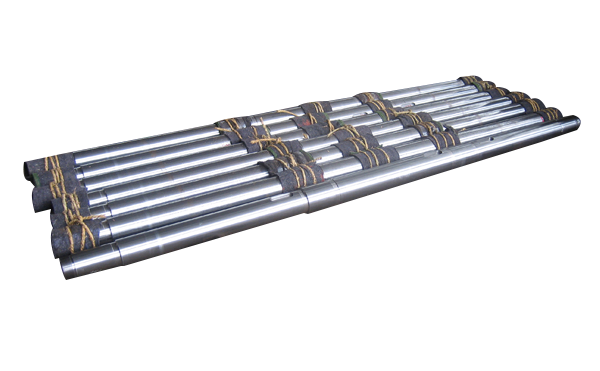

Continuous Casting Roll Core Shaft

The continuous casting roll core shaft mainly supports and drives the continuous casting roll, ensuring the stability and continuity of the continuous casting process.

Roll sleeves, as indispensable components in industrial production, are widely used in various rolling mills, crushers, mixers and other mechanical equipment. Their main function is to protect the roll core from direct wear and corrosion, thus extending the service life of the entire roll.

Blog

Address: No.1 Hengan Road, Tianning District, Changzhou City (Zheng Lu Heping Industrial Park)

Contact: Mr. Xu

Mobile:13815019479/15261117373

E-mail:xujiahui24@163.com/baihuixj@163.com

Copyright©2024 Changzhou Baihui Machinery Manufacturing Co., Ltd. Rights Reserved.